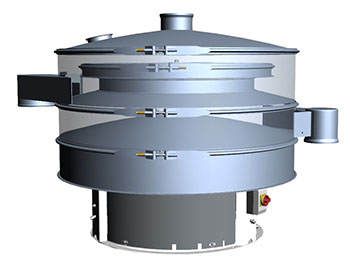

Dedusting sieving machine

Dedusting sieving machine ideal solution

Removing dust is perhaps the most difficult task in sieving technology. After all, the largest amount of products is on the screen deck and hinders the supply of new product. The solution of dedusting lies mainly in increasing the discharge capacity, in particular the discharge capacity of the product on the screen deck. The BÈTA dedusting sieving machine is the ideal sieving machine for this!

Normally, the product is on its way from the screening deck to the outlet, which is located somewhere in the wall of the machine. With only one outlet, there is, as it were, a traffic jam of product on its way to that one outlet. If the supply is too high, the screen deck will fill up and the process will stop.

Dedusting sieving machine

The BÈTA dedusting sieving machine has a sieve deck that is one size smaller than the machine suggests. As a result, the product that ends up on the outside of the screen deck is no longer on its way to the outlet, but falls directly off the screen deck and ends up on the convex bottom, which forces the product towards the outlet of the BÈTA dedusting sieving machine. In this way the screen deck remains free of product for much longer and a considerably higher capacity and efficiency is achieved.

Would you like to know which type of vibratory separators is best suited for your situation? Then let one of our specialists advise you. For this you can contact us by phone on: +31 79 341 55 18 or simply via the button below!

Neem contact op- Standard filter housings

- Whey sieving machine

- Scalper screening machine

- Filter bags

- High flow filter cartridges

- Meltblown cartridge filter

- Multi-deck screening machine

- Dedusting sieving machine

- Wound filter cartridges

- Auxiliary systems

- Multiflow filter cartridges

- Custom-made filter housings

- Industrial filter housings

- High pressure filter housings

- Self-cleaning filters

- Standard screening machine

- Modular screening machines

- Horticultural filter

- Screen decks

- Separator

- Porous sintered metal

- Straight-flow screening machine

- Pleated filter cartridges

- Filter modules

- Cellulose filter cartridges

- Carbon filter cartridges

- Bernoulli filters

- Filter plates