Butterfly valves

Butterfly valves from BÈTA industrie

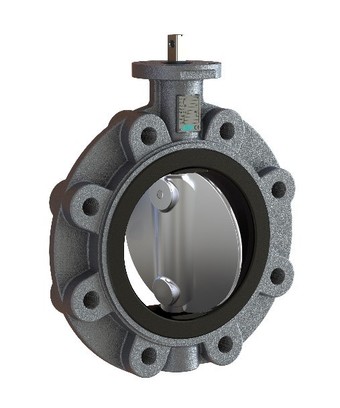

BÈTA industrie has a wide range of butterfly valves, because the butterfly valves are made in various designs. A distinction can be made in the way in which the damper blade is mounted in the housing. Each version has specific advantages and is therefore used in different applications. The advantage of a butterfly valve is that it is a relatively simple valve, short installation size, available in various materials, large sizes and easy to automate.

Different types of butterfly valves

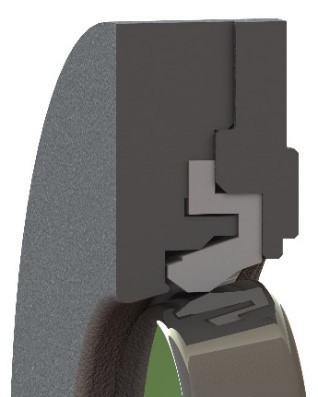

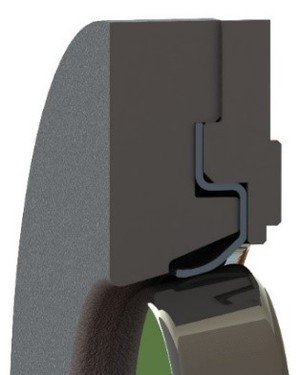

Concentric versionThe concentric butterfly valves are the most commonly used butterfly valves. Due to the concentric design, the shaft sits exactly in the middle of the damper blade. As a result, the damper blade always remains in contact with the seal in both open and closed position. This butterfly valve is fine for less critical applications and certainly in situations where the valve is opened and closed very regularly. These valves are available as wafer, lug, flanged or double flanged version and various sealing materials.

High performance valvesIn addition to concentric butterfly valves, butterfly valves are also available with a Double, Triple or even Quadrupel eccentric high performance design. The big difference is that with these valves the damper blade is mounted on the shaft, so that the load on the seal is less great. When the valve is open, there is no contact with the seal. As a result, it will deform or wear less and the operability of the valve is optimal. In applications where the valve is used less frequently, this is the better choice. This makes the seal more precise and reliable, making these valves suitable for use in critical processes. For example at high temperatures, higher pressures or where pressure can escape on both sides of the seal. These valves are available as wafer, lug, flanged or double flanged version.

Material types of the butterfly valves

All butterfly valve models are available in different material types. Ask our experts which type of material is most suitable for your purpose.

- Ductile Iron, GGG40,DIN 1691 60-40-18,ASTM A536 400-18, BS 1452

- Carbon Steel, ASTM A216, GS-C 25, BS 1504

- Stainless Steel, 1.4408, A351-CF8M

- Aluminum Bronze, BS1400, ASTM B148 AB2, G-CuAl10Ni

- Bronze Casting, C-CuSn10Zn, DIN 1705 (RG10), ASTM B584 LG1

- Titanium (Gr.2, Gr.5, Gr. 7)

- Nickel alloys (Hastelloy®)

- Incoloy®

- Inconel®

- Monel

- Alloy 20

- (Super) Duplex

- (UNS S31803, S31254, S32750, S32760, ZERON100 etc.)

Butterfly valve sealing materials

- NBR

- HNBR

- Silicone

- Graphite

- EPDM

- FKM / Viton

- PTFE / Teflon

- Metal seat

- Valve Controls and Options

The butterfly valves are supplied as standard as manual control, but each valve can be fitted with:

- Pneumatic Actuators (single and double acting)

- Electric Actuators (possibly with spring return)

- Gear drive

- Limit switch boxes

- Position indicators

- Lid lock

- Heart Protocol

- Positioner

High quality butterfly valves

All our butterfly valves are extensively tested during and after production (on pressure, functionality and torque) in accordance with the API-598 or BS 5155 guidelines and according to our internal and international quality standards such as, KIWA, WRAS, Lloyds RS, Bureau Veritas, Det Norske Veritas, China Classification Society, American Bureau of Shipping, TUV/ABS, EN 593 and API 609. Our butterfly valves are available in sizes from DN 40 (1½″) to DN1600.

Are you curious about the butterfly valves or would you like more information? Please contact us via the button below. Our specialists are happy to help you!

Neem contact op