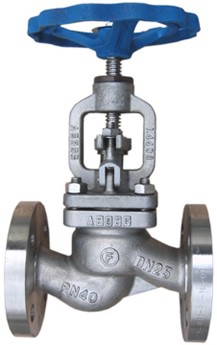

Globe valves, bellows valves and plunger valves

Valve seal

A globe valve is extremely suitable for control applications and is often used with both manual and automated operation. This type has interesting properties, especially as a control valve. The globe valve is therefore often used as a control valve in industry for liquids, steam and gases. The globe valve is available in a flanged and threaded version, from low pressure to PN 100 (ANSI 2500#) and with electrical, pneumatic, hydraulic or mechanical operation in open/close function. The globe valve is available in cast iron, cast steel, stainless steel or high-quality alloys (GG25, ggg40.3, GS-C25, 1.4408, 15Mo3, 13CrMo44, 10 CrMo9-10, etc.).

Bellows valves

Bellow valves (bellow sealed globe/gate valves) are generally used more often with 'hazardous' mediums, such as ammonia or chlorine. Due to the construction with the bellows around the rod and the special spindle seal, emission along the shaft meets the highest requirements. Our bellows valves are designed for years of emission-free sealing. Reliability, even after years of maintenance-free use, is paramount. The bellows valves are available in almost all common metals such as Hastelloy, Incoloy, Inconel, Monel and Titanium.

Plunger valves

Plunger valves are steam valves that are guaranteed to close, even under the toughest conditions. Plunger valves have a large sealing surface and excellent control properties. The solid design has proven itself over the years. The robust construction guarantees a long service life and high operational reliability. In addition, the valves are seatless, so that contamination is not a problem. These special features make plunger valves low-maintenance, which saves a lot of costs.

Valve, bellows and plunger valves from BÈTA industrie

At BÈTA industrie you have come to the right place for valves, bellows and plunger valves. Our products have a high quality and are quickly available from stock. As explained above, you can read that each type of valve is used for specific circumstances. This way, one of these applications will always fit into your production process. Would you like to know which application fits best in your process or system? You can easily contact one of our specialists. This can be done by telephone on +31 79 341 55 18 or simply via the button below!

Neem contact op