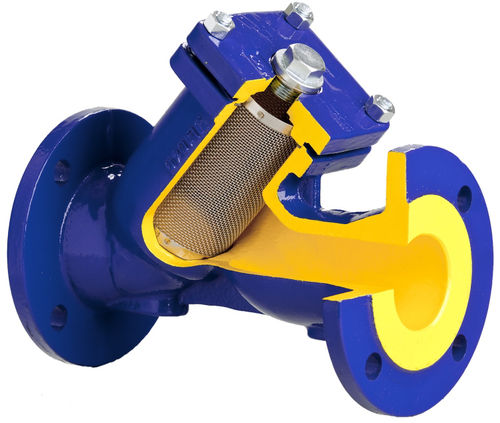

A Y-strainer, suitable for many applications

A Y-strainer is the most common strainer type, suitable for many applications. Can be used in horizontal and vertical pipes. The Y-strainer gets its name from the shape of the housing that forms a “Y”. In water and steam installations, a strainer filter is the standard and is placed to protect critical equipment. When the medium flows into the strainer filter, it passes through a sieve that traps the unwanted particles. The medium is led inside the sieve and then flows out through the sieve again. This keeps dirt particles inside the sieve. This does mean that the Y-strainer has a fixed flow direction, which is indicated by an arrow on the housing.

Clean or replace strainer

When the strainer's screening machine is dirty, it must be cleaned. Periodic cleaning should take place and the frequency depends on the contamination of the medium that passes through the strainer filter. In principle, for cleaning, the lid must be dismantled in order to remove the sieve from the strainer filter, to clean or replace it and then to place the sieve back in the strainer filter. The filter can only be cleaned when there is no more pressure on the system. This is of course not always possible from an economic perspective, especially if the filter has to be cleaned often. That is why a drain opening is often provided in the lid, where the dirt can be drained off using the medium with the aid of a small valve. Normally a ball valve valve is used for this.

Y-strainer models

Y type strainers are mainly used for liquid applications to protect downstream equipment from particulates including; dirt that can otherwise affect performance if it settles and builds up. Y-strainers are available from DN10 to DN1200 where the standard sieve opening size varies between 0.1 and 3.0 mm. Different sieve openings are also available. For a greater flow capacity and a larger filter surface, a switch is made to a basket filter or to a T-filter.

Y-strainers, duplex strainer, T strainers are available in the following material type:

- Cast iron

- Ductile iron

- Cast steel

- Stainless steel

- Duplex

- Special material types

Strainers bij BÈTA industrie

BÈTA industrie has a wide range of Y-strainers and T-strainers. We can also provide Duplex, Simplex and filter strainers. Would you like more information about the strainers? Feel free to contact us via +31 79 341 55 18 or simply via the button below!

Contact us